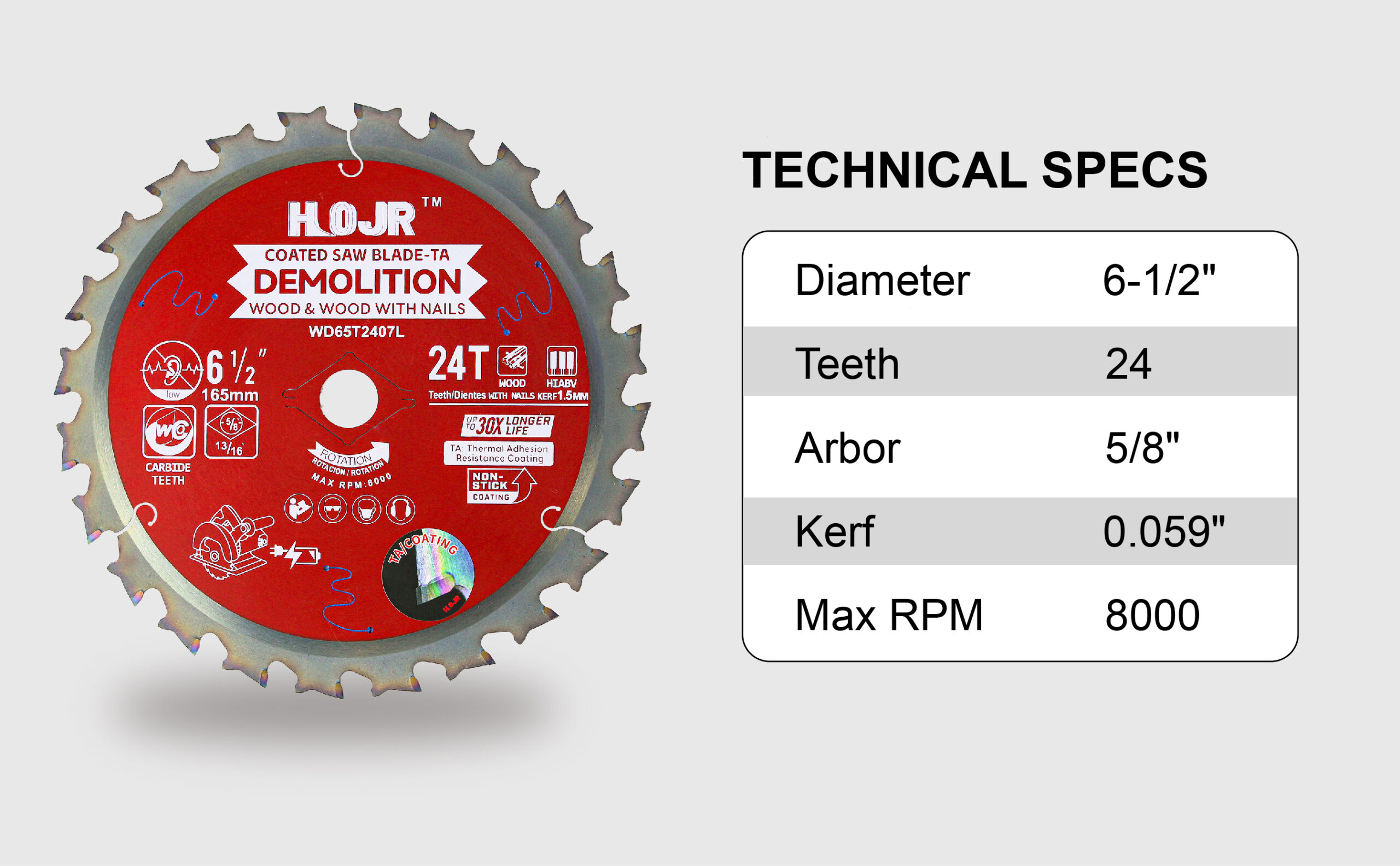

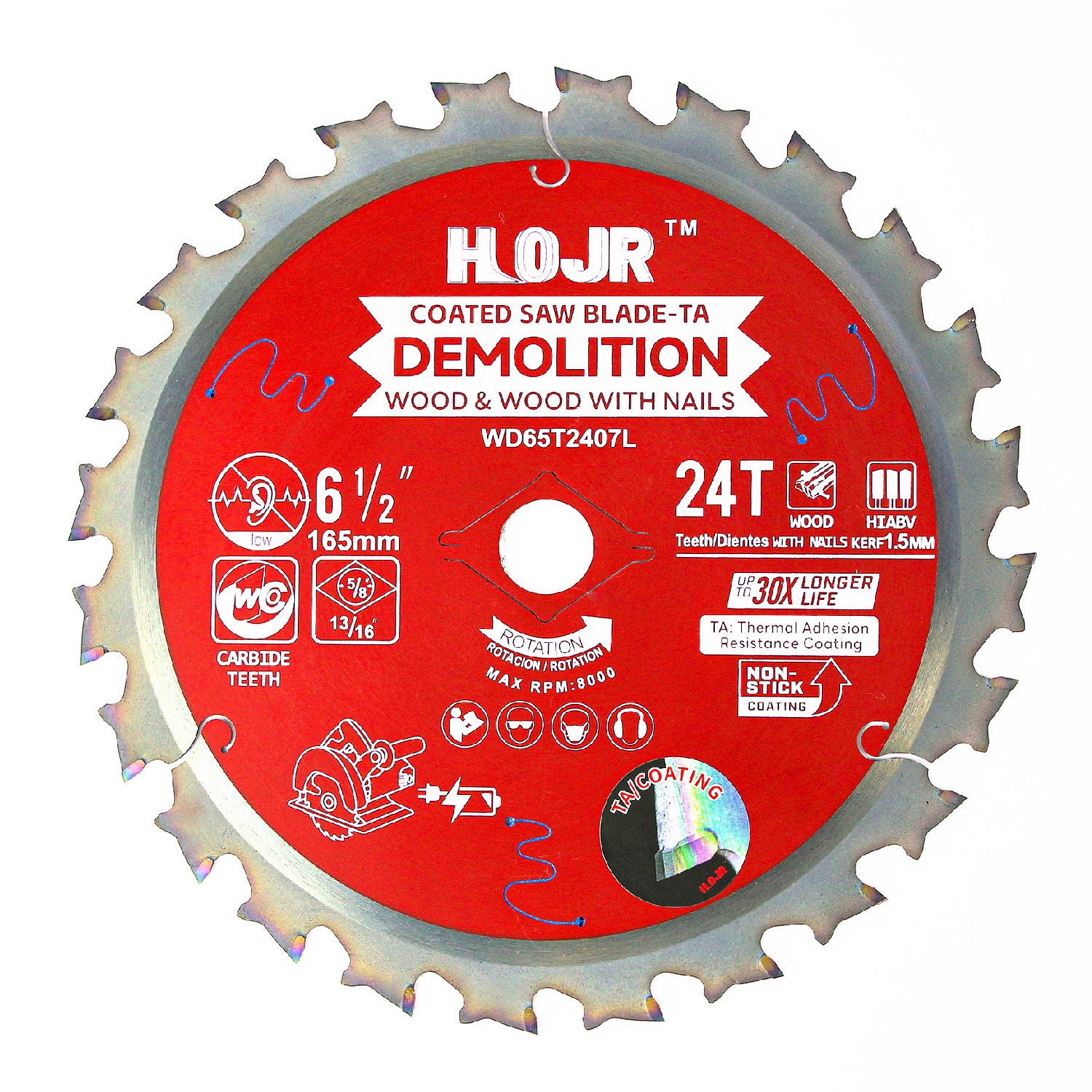

HOJR 6-1/2″ 24 Tooth Framing/Demolition Circular Saw Blade, For wood and wood with nails,Special Anti-Thermal Adhesion Coating On Cutting Tip – TA,Item: WD65T2407L

Cuts Applied Material:

suitable for general wood and wood with nails.

Description:

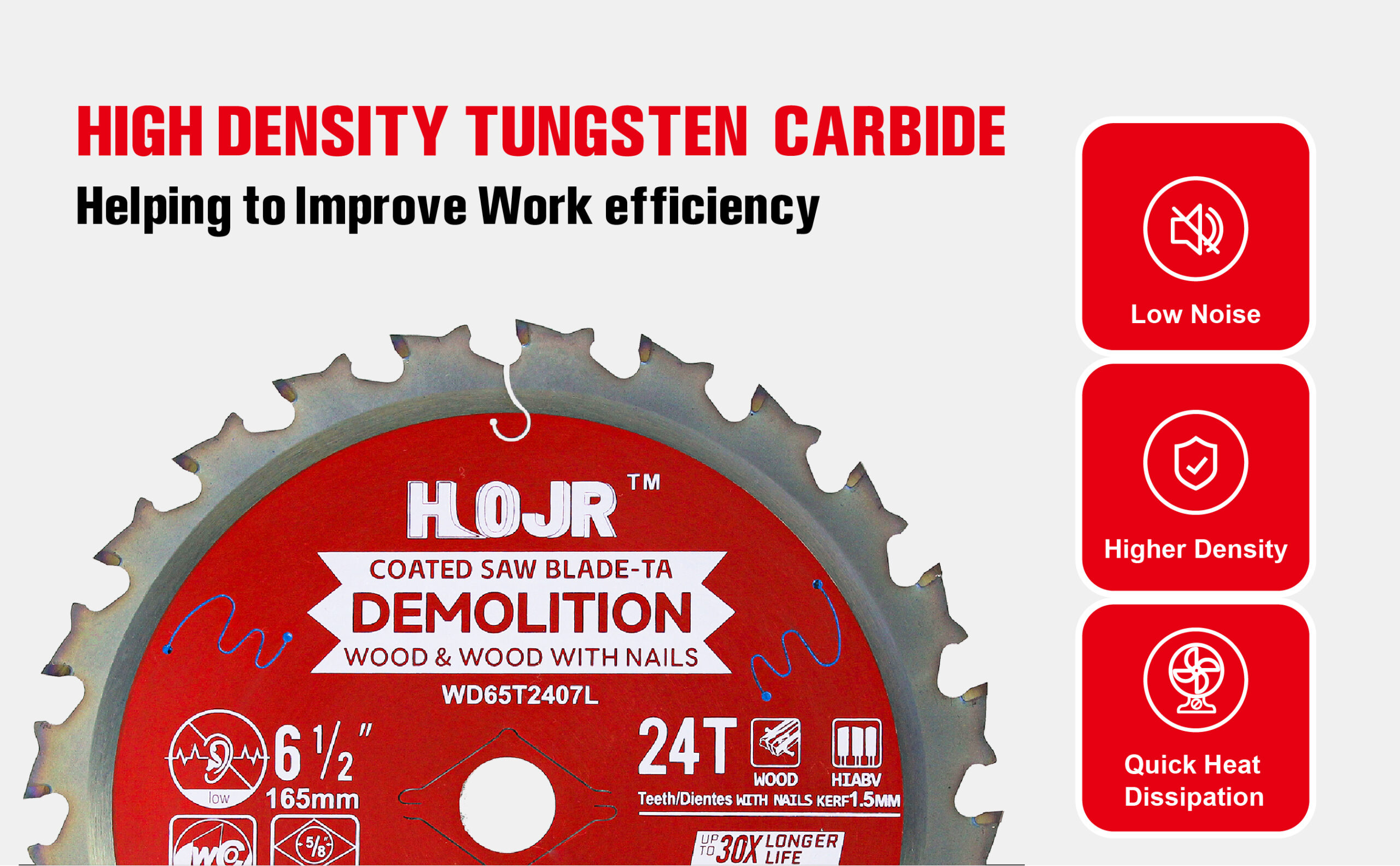

HOJR’s Framing/Demolition saw blade is exceptionally idea for demo applications — cut farming wood and wood with hidden nails, its premium HI-Density carbide teeth provide clean cuts and extreme life and durability in the remodeling and demolition ,it also offers laser-cut, anti-vibration slots that eliminate the need for stabilizers, and TA non-stick coating, this thermal adhesion resistance coating redefines the cutting performance of the saw blade. The coating acts on the blade's carbide tips, its hardness is up to HV4000+,The work life of blade can be extended more than 30 times.

Features:

- 1, Up to 30x longer life than regular blades.

- 2, TA coating (Thermal adhesion resistance coating) protective blade coating protects against gumming and corrosion

- 3, Anti-nail kickback tooth design resists nails on impact

- 4,Thin Kerf requires less power and allows for faster feed rate.

- 5, premium HI-Density carbide teeth are sharpened to provide clean cuts and exceptionally long life.

- 6, Laser cut stabilizer vents trap noise and vibration keeping it cool and reducing blade warp

- 7,Laser cut expansion slots reduces blade warping

- 8, Ideal for Extreme framing and demolition applications

FAQ:

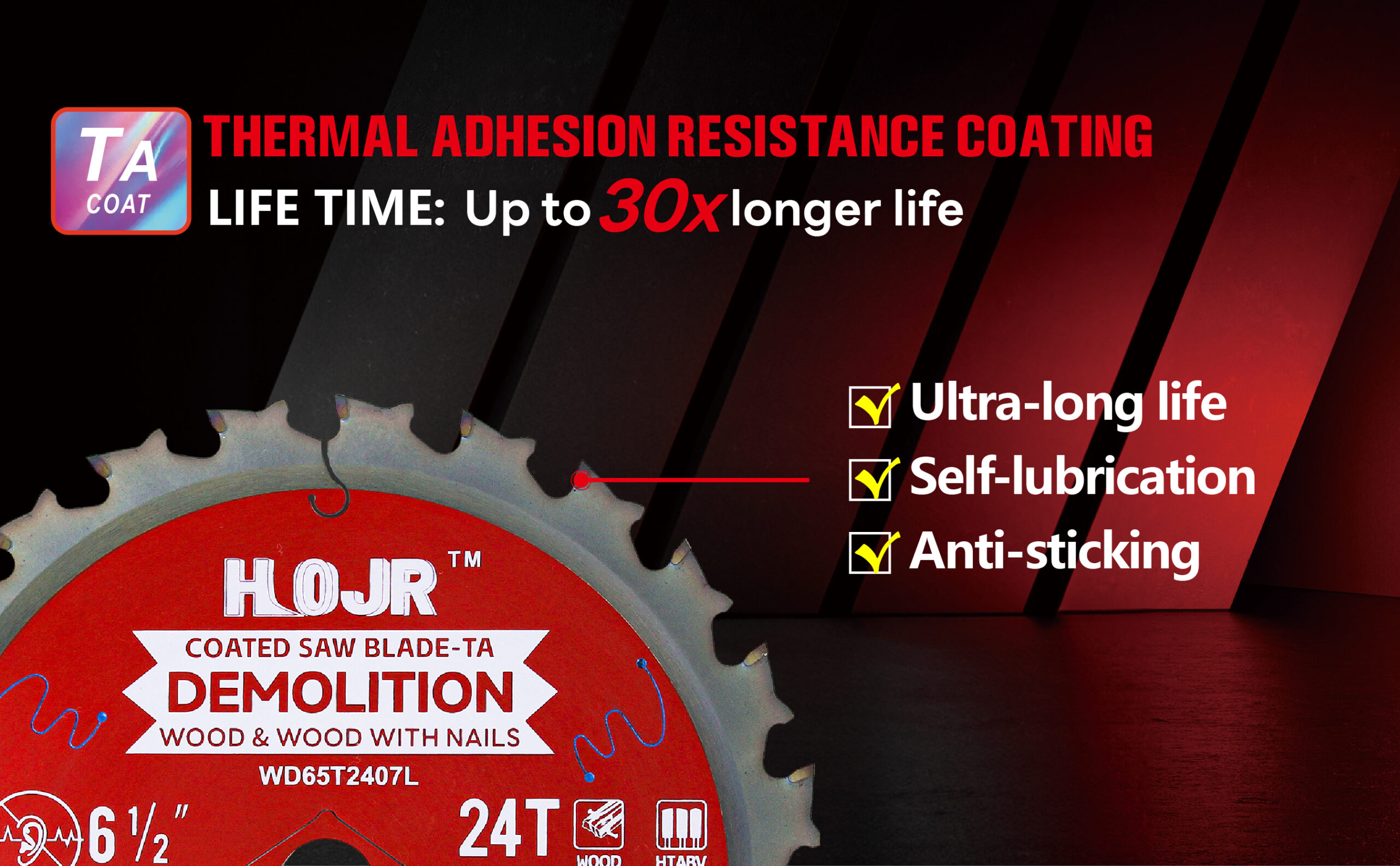

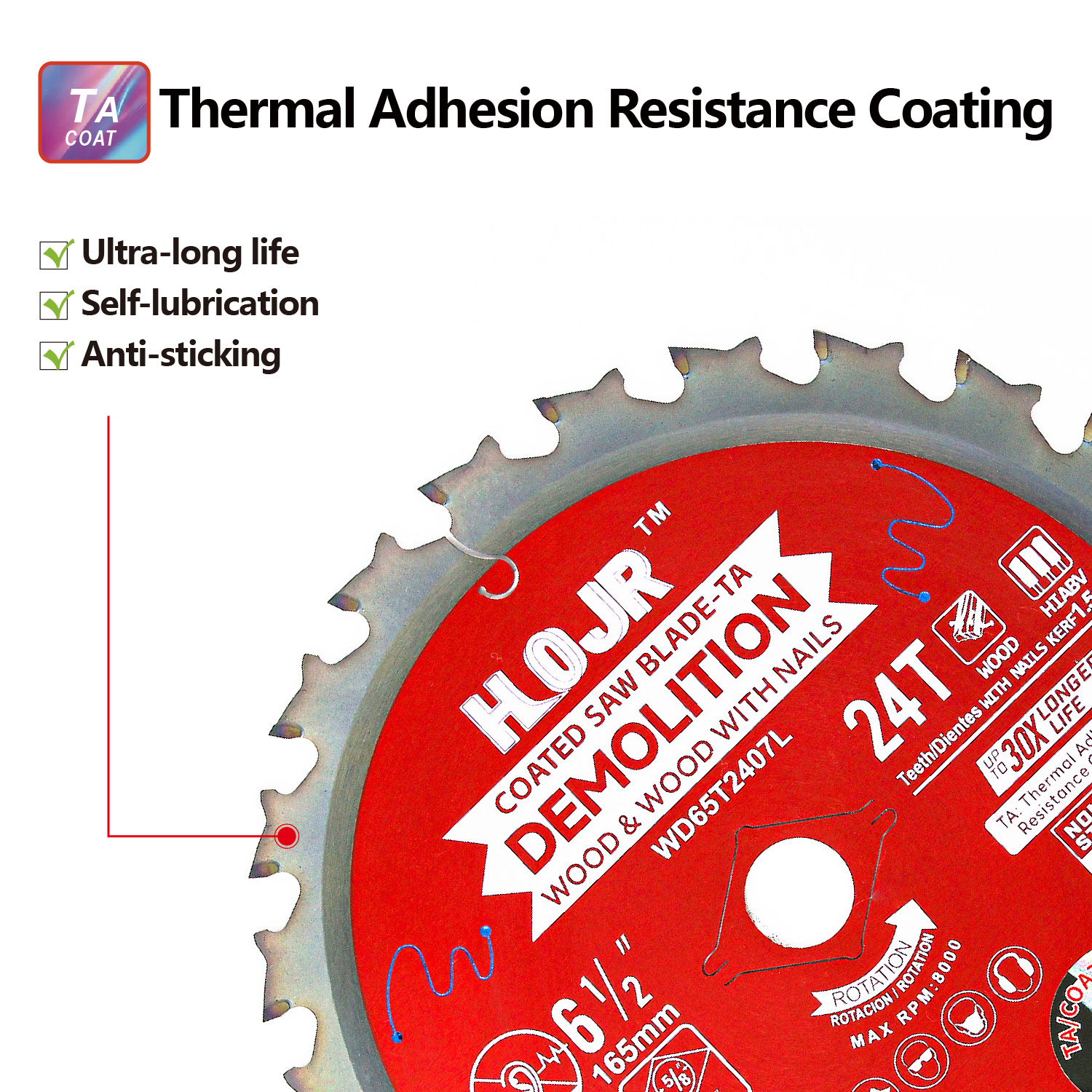

1. What is the TA coating?

TA coating is the thermal adhesion resistance coating, it redefines the cutting performance when used on saw blade.

1, Ultra-long life: its hardness is up to HV4000+,which can greatly extend the work life of blade more than 30 times than others

2, Self-lubrication: It has a minimum friction coefficient to optimize the finish of the wood surface.

3,Anti-sticking: it reduces friction and heat buildup for less drag, gumming, and corrosion.

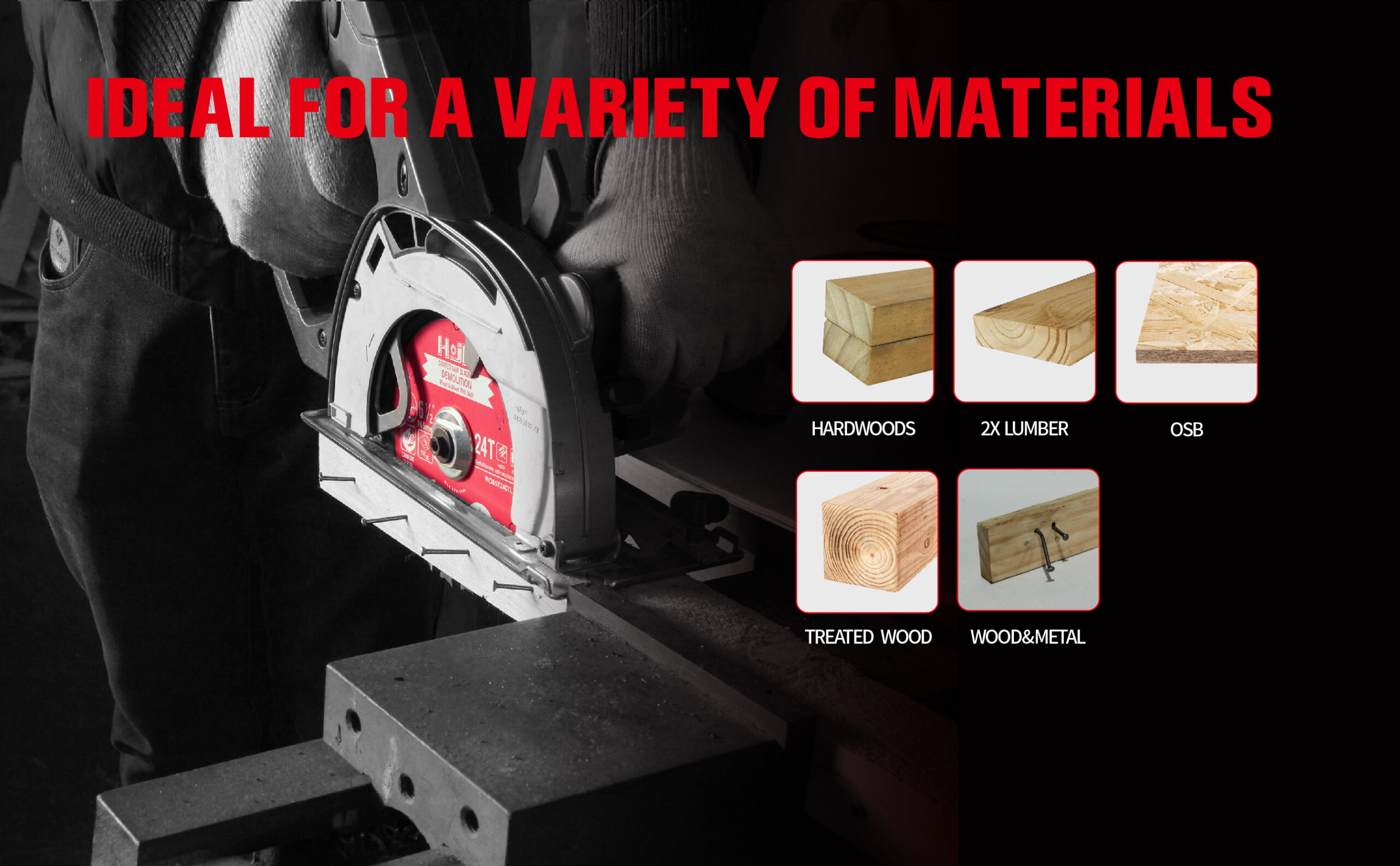

2. Which woods are TA-coated circular saw blades suitable for?

TA-coated circular saw blades are suitable for a wide range of woods, including hardwoods, softwoods, 2x lumber, pressure treated wood, OSB, plywood and other general woods.

3. How do i properly care for my TA-coated circular saw blades correctly?

You can operate as following tips to maintain cutting efficiency, extend blade life, and ensure safe operation in woodworking projects.

● regular cleaning

● sharpening as needed

● storage in a suitable environment

Detail Image

Leave a Reply